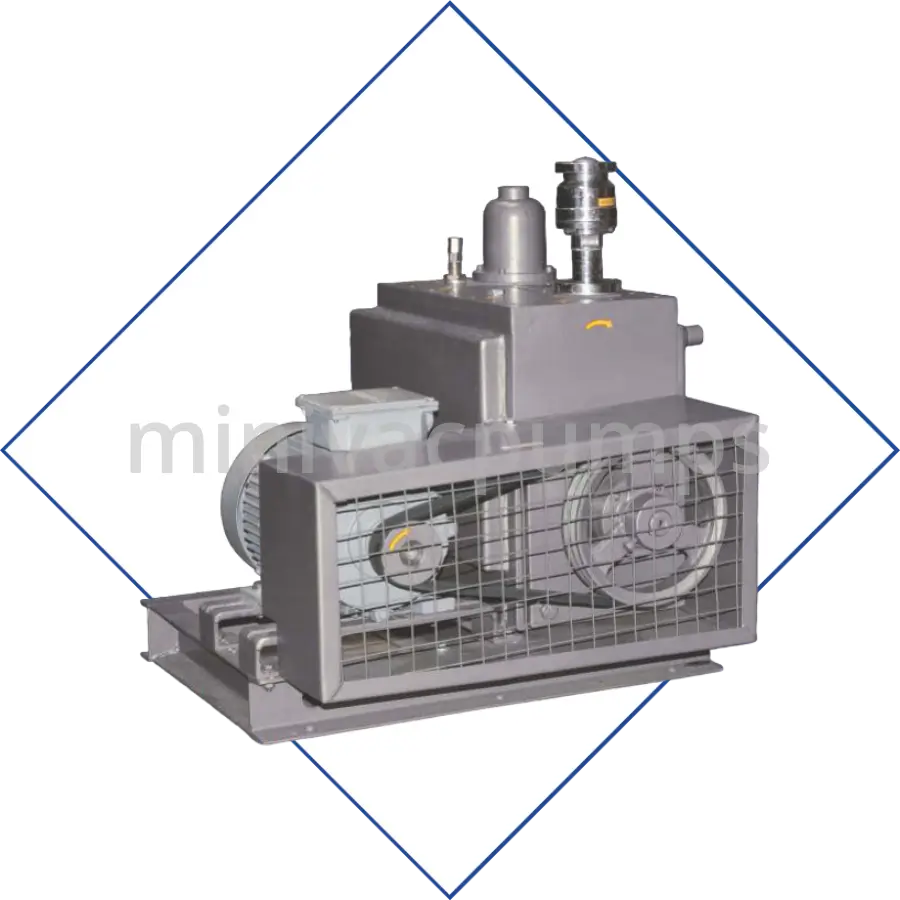

Oil Sealed High Vacuum Pumps

Principle Working

An Oil Sealed rotary vane high vacuum pump consists of a housing, an eccentrically installed rotor, vanes that move under centrifugal and resilient forces, an inlet and an outlet valve. The inlet valve, if available acts as a vacuum safety valve that always remains open during the working of the pump. The working chamber is located inside the housing and is restricted by the stator, rotor and the vanes. The eccentrically installed rotor and vanes divide the working chamber into two separate compartments with variable volumes. As the rotor turns, gas flows into the enlarging suction chamber until it is sealed off by the second vane. The enclosed gas is then compressed until the outlet valve opens against atmospheric pressure. The outlet valve is oil-sealed. When the valve is open, a small amount of oil enters the suction chamber and not only lubricates it but also seals the vanes against the housing

We are Manufacturer, Exporter and Supplier of Oil Sealed High Vacuum Pumps

Applications

Technical Specification

Single Stage

| Model | Free Air Displacement | Ultimate Vacuum (Torr) | Electric Motor | Oil Capacity Liters |

Dimensions (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| LPM | m3/hr | with gas ballast | without gas ballast | HP | RPM | L | B | H | ||

| S-50 | 50 | 3 | 2 | 0.05 | 0.25 | 1440 | 3 | 407 | 300 | 328 |

| S-100 | 100 | 6 | 2 | 0.05 | 0.25 | 1440 | 4.5 | 457 | 372 | 328 |

| S-150 | 150 | 9 | 2 | 0.05 | 0.5 | 1440 | 4.5 | 457 | 372 | 328 |

| S-325 | 325 | 19.5 | 2 | 0.05 | 1 | 1440 | 8 | 660 | 490 | 510 |

| S-600 | 600 | 36 | 2 | 0.05 | 1.5 | 1440 | 8 | 610 | 415 | 510 |

| S-750 | 750 | 45 | 2 | 0.05 | 2 | 1440 | 8 | 660 | 440 | 510 |

| S-1500 | 1500 | 90 | 2 | 0.05 | 3 | 1440 | 20 | 890 | 585 | 755 |

| S-2000 | 2000 | 120 | 2 | 0.05 | 3 | 1440 | 25 | 890 | 685 | 755 |

Double Stage

| SD-50 | 50 | 3 | 0.1 | 0.005 | 0.25 | 1440 | 3 | 407 | 300 | 328 |

| SD-100 | 100 | 6 | 0.1 | 0.005 | 0.25 | 1440 | 4.5 | 457 | 372 | 328 |

| SD-150 | 150 | 9 | 0.1 | 0.005 | 0.5 | 1440 | 4.5 | 457 | 372 | 328 |

| SD-325 | 325 | 19.5 | 0.1 | 0.005 | 1.5 | 1440 | 7 | 610 | 415 | 510 |

| SD-600 | 600 | 36 | 0.1 | 0.005 | 2 | 1440 | 8 | 660 | 540 | 510 |

| SD-750 | 750 | 45 | 0.1 | 0.005 | 3 | 1440 | 8 | 610 | 590 | 510 |

| SD-1500 | 1500 | 90 | 0.1 | 0.005 | 5 | 1440 | 25 | 890 | 765 | 755 |

| SD-2000 | 2000 | 120 | 0.1 | 0.005 | 5 | 1440 | 35 | 890 | 840 | 755 |